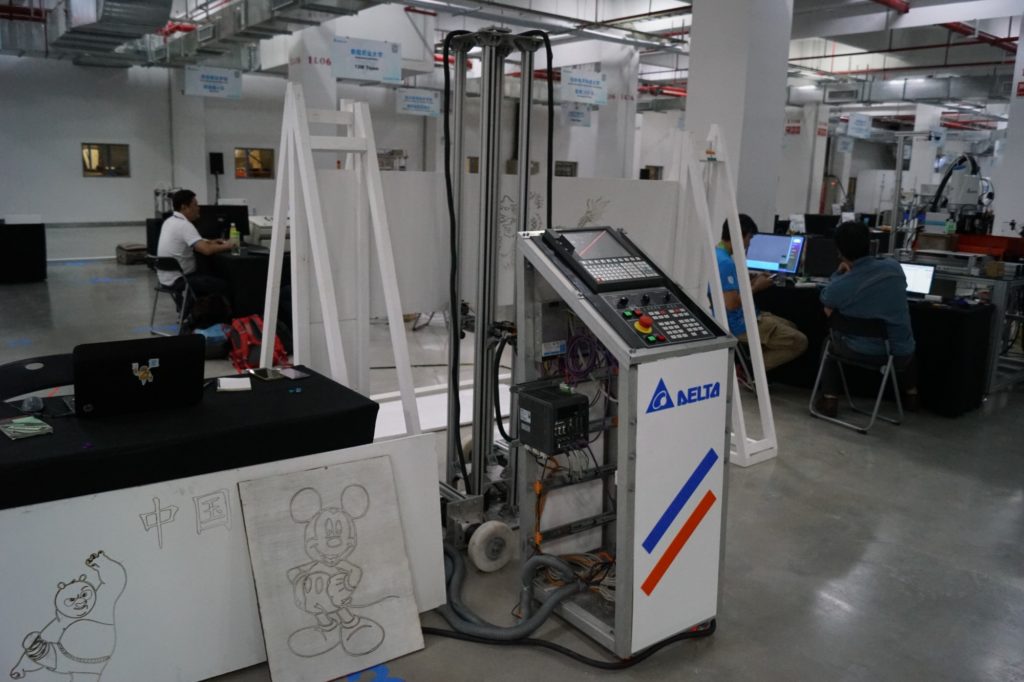

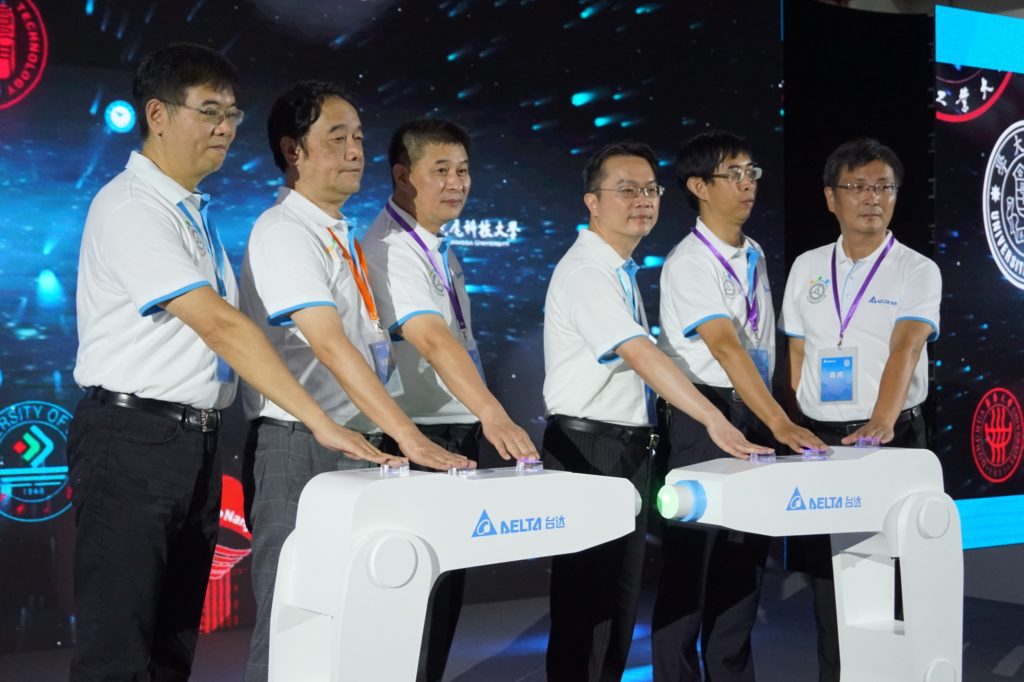

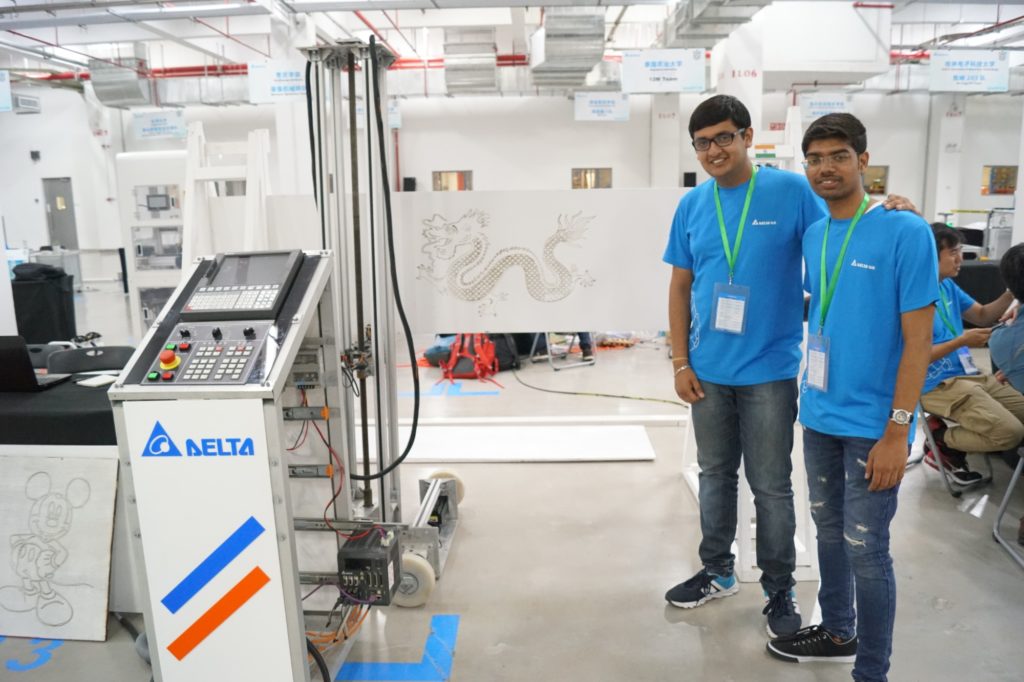

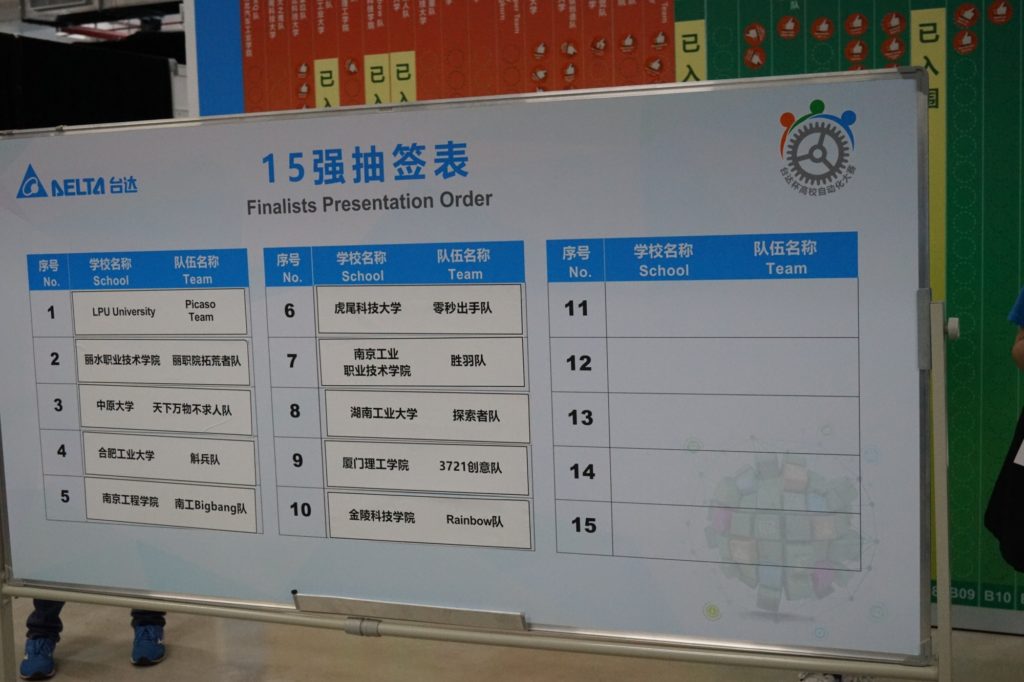

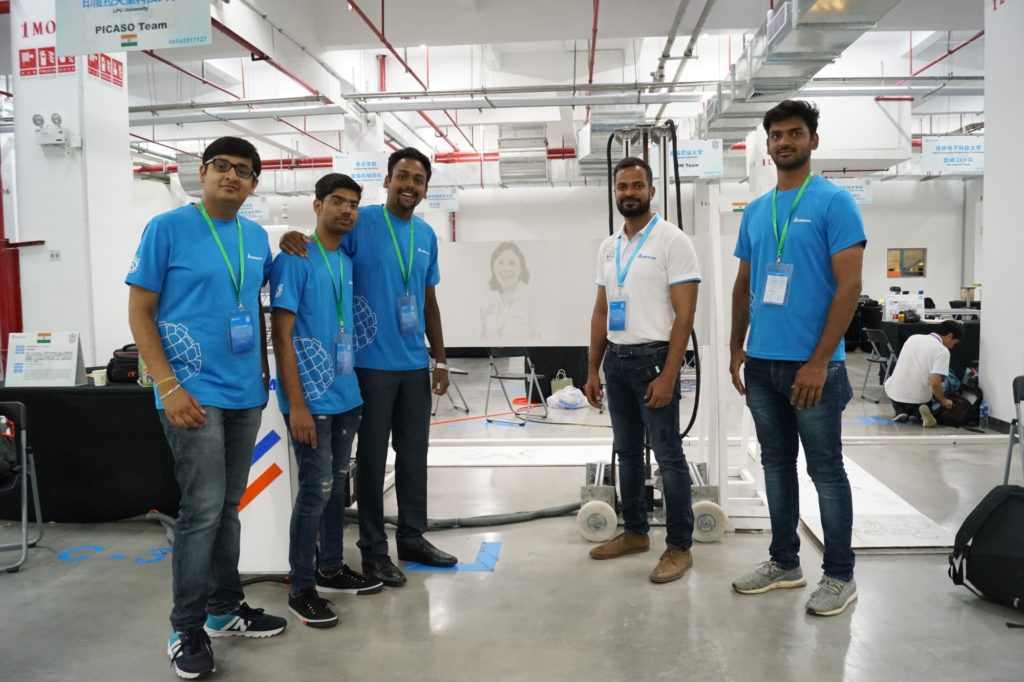

The 4th Delta Advanced Automation Contest 2017, Wujiang plant of Delta Group, China

The 4th Delta Advanced Automation Contest (the “Contest”) is themed “Seeking Smart Manufacturing Talents”. The Contest is sponsored by the Automation Technology Teaching Steering Committee for Higher Education under the Ministry of Education, the Chinese Association of Automation, and the Industry and Information Industry Vocational Education Teaching Steering Committee under the Ministry of Education. It is an innovative technology competition for automation applications organized by the Delta Group.

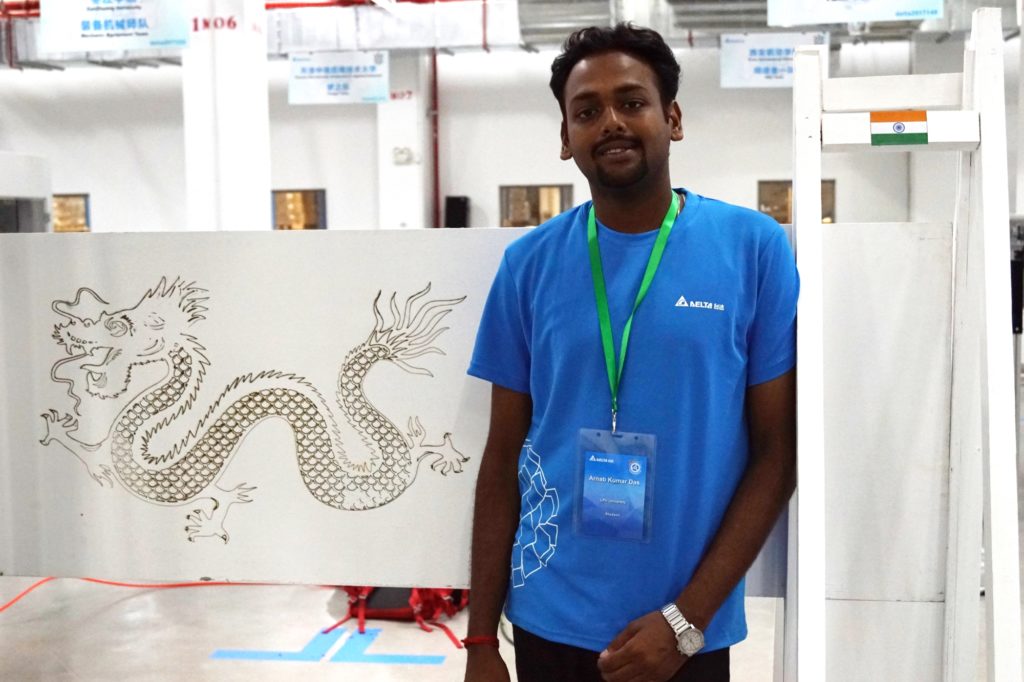

I (Arnab Kumar Das), along with my friends Vinod V. and Nikhil Goyal participated and won the First Prize. Here we have documented our manufacturing and competition. The competition happened from July 24-26, 2017 at the Wujiang plant of Delta Group, China.

We are the first one from INDIA to win First Prize in this International Competition.

The Project

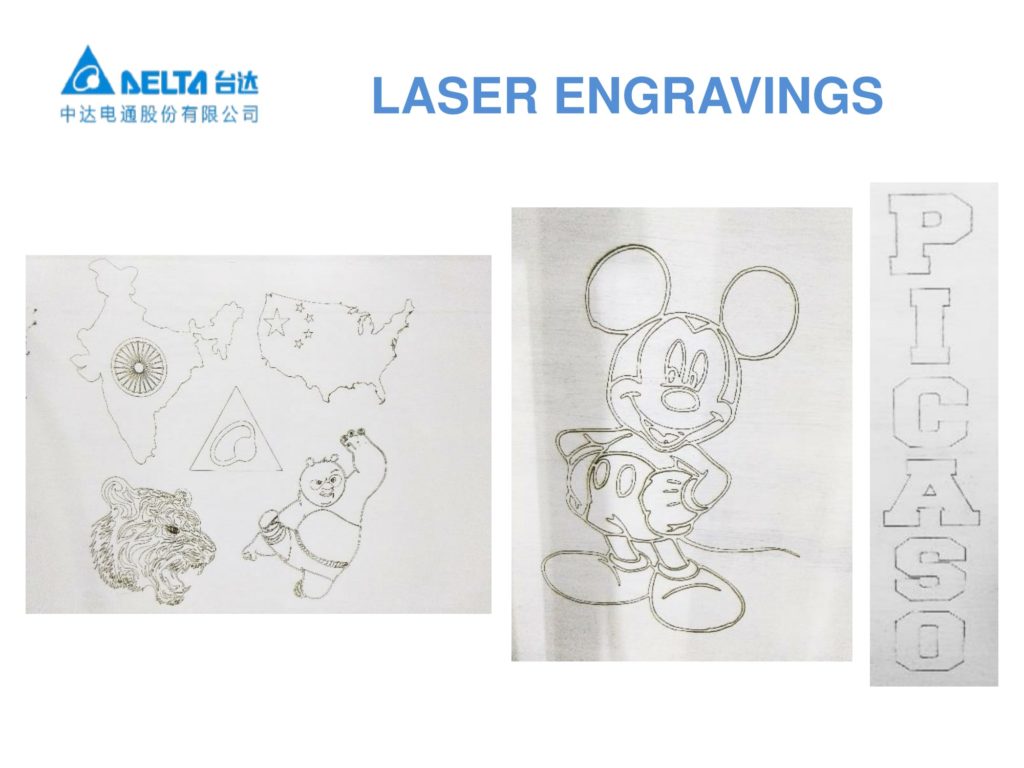

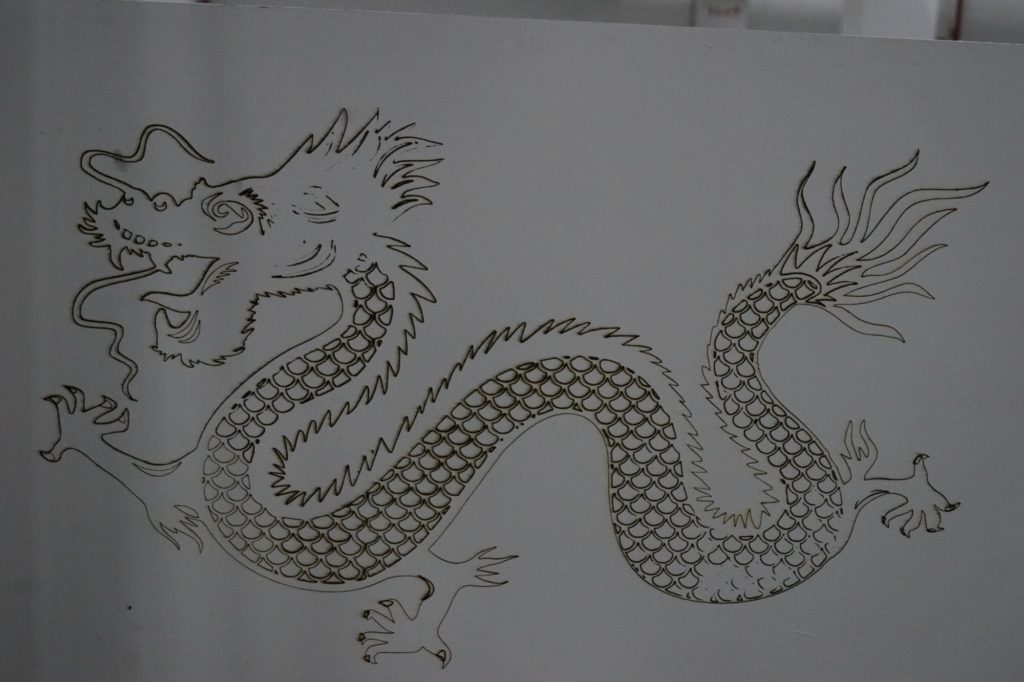

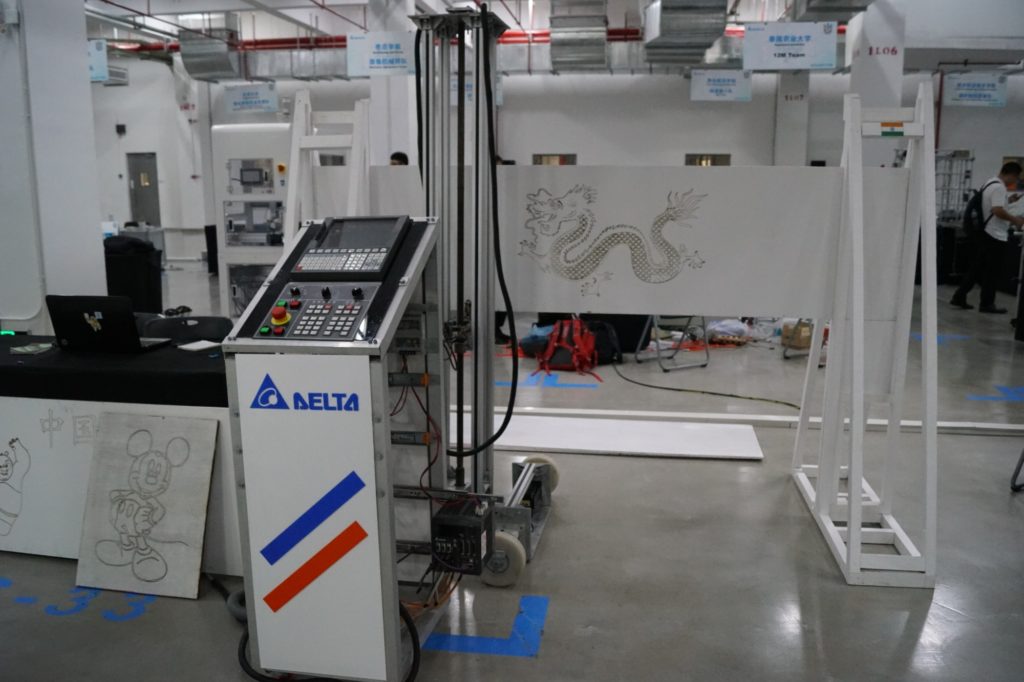

PICASO 4.0 is a Computer Numeric Control (CNC) machine-based Multi-Axes Motion Control Machine for Automated Vertical Laser Engraving / Mechanical Milling solution for brick walls, concrete, glass, wood etc. or any vertical plane surface that can accept laser. Unlike conventional CNC it has no horizontal workspace constraint [ INFINITE X AXIS ] and can engrave long walls. PICASO 4.0 can be used for upright walls, glass, doors, etc., do not have to remove the door or glass, to provide high convenience. In addition to laser engraving, it also can be replaced by other tools, painting or cutting and other actions. PICASO 4.0 Painting the future!! is made by Arnab Kumar Das, Veluguri Vinod and Nikhil Goyal of Lovely Professional University, India Sponsered by Delta Electronics.

World’s First Wall Engraving/Milling CNC Machine that works on the vertical surface without any X-Axis Limits.

Applications:

Case 1:

Customer Requirement:

A customer wants the wall of his house to be painted with his own customized design.

Solution:

The customer uploads the design to the cloud server, brings PICASO 4.0, aligns its painting tool towards the wall, put it into painting mode, set the painting area and enjoys the output.

Case 2:

Customer Requirement:

A customer has a glass door at his office entrance and he wants his company’s logo to be engraved on it but he does not want to invest in a new door and also he wants to avoid disassembly and reassembly of the door.

Solution:

Bring PICASO 4.0, align its laser tool towards the glass door, upload the company’s logo to the cloud server, put it into laser engraving mode, set the engraving area and enjoy the output.

Case 3:

Customer Requirement

A customer has a large factory that has a concrete wall around its perimeter. The customer wants his perimeter to be painted with the least labour cost and minimum time.

Solution:

Configure PICASO 4.0 to move around the perimeter wall and paint.

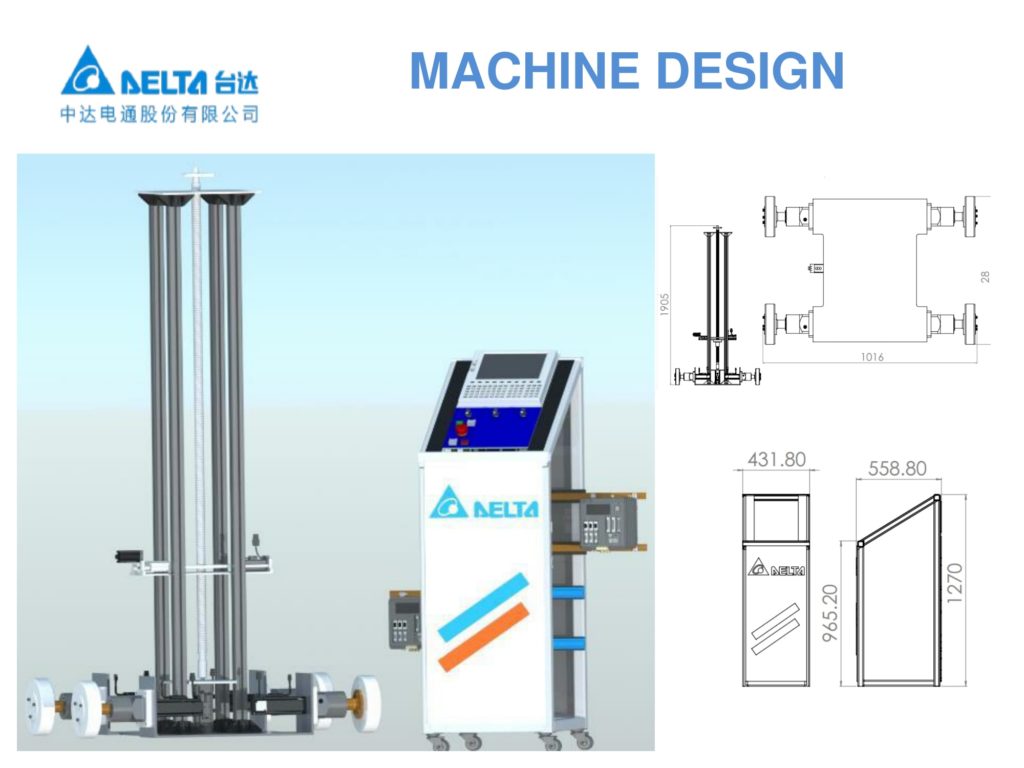

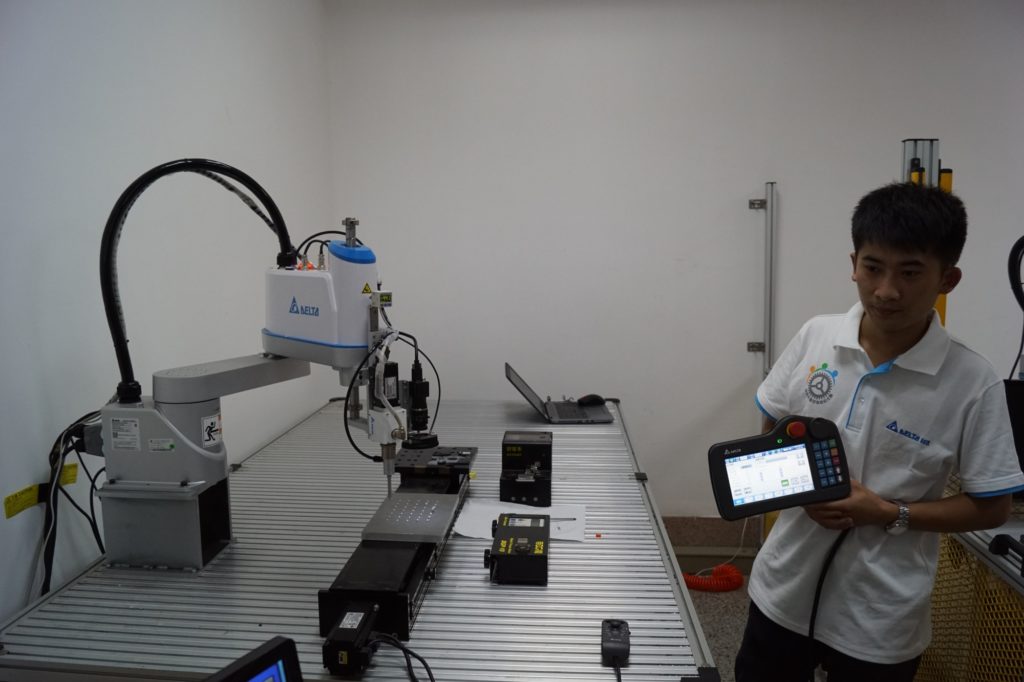

Design

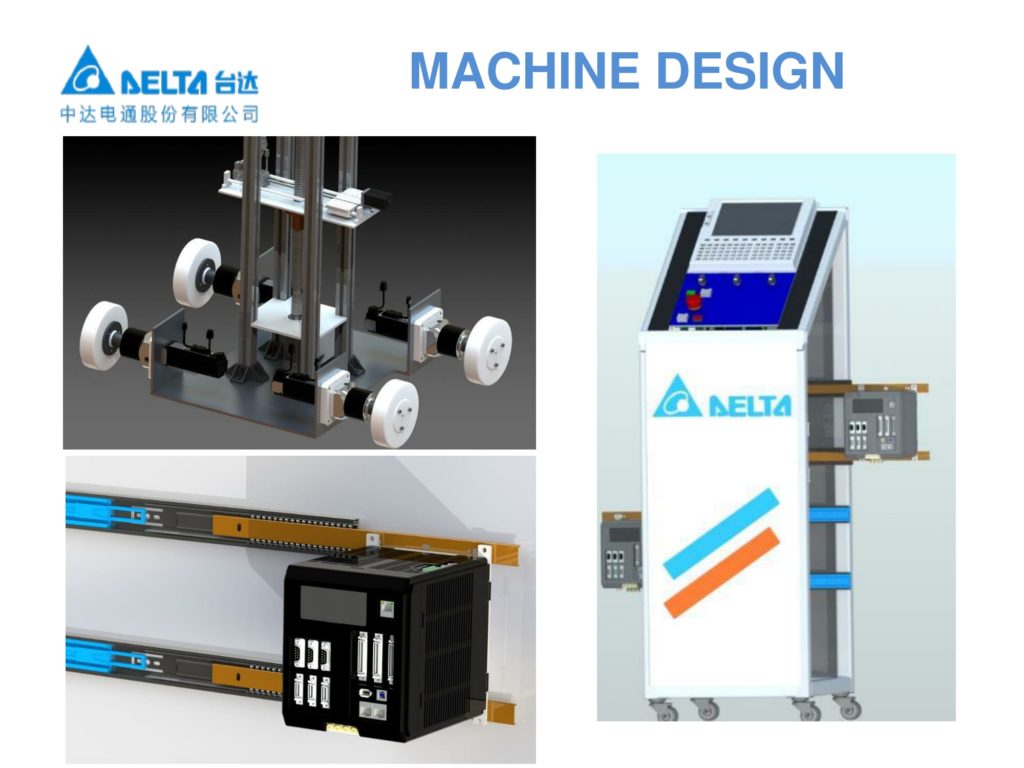

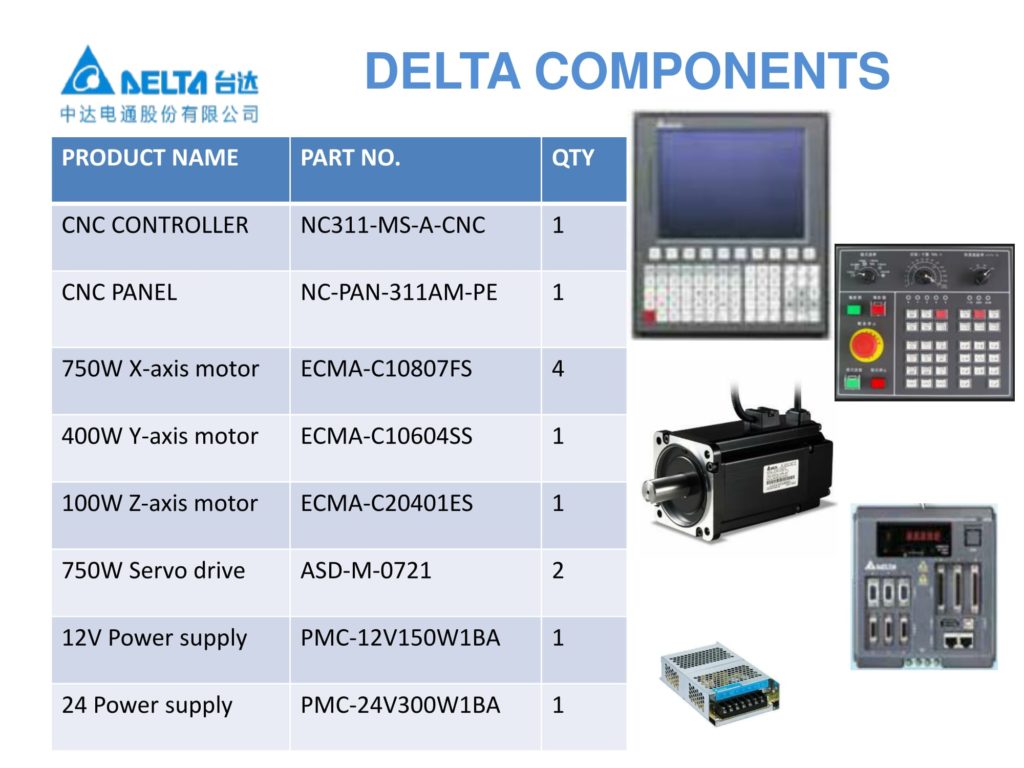

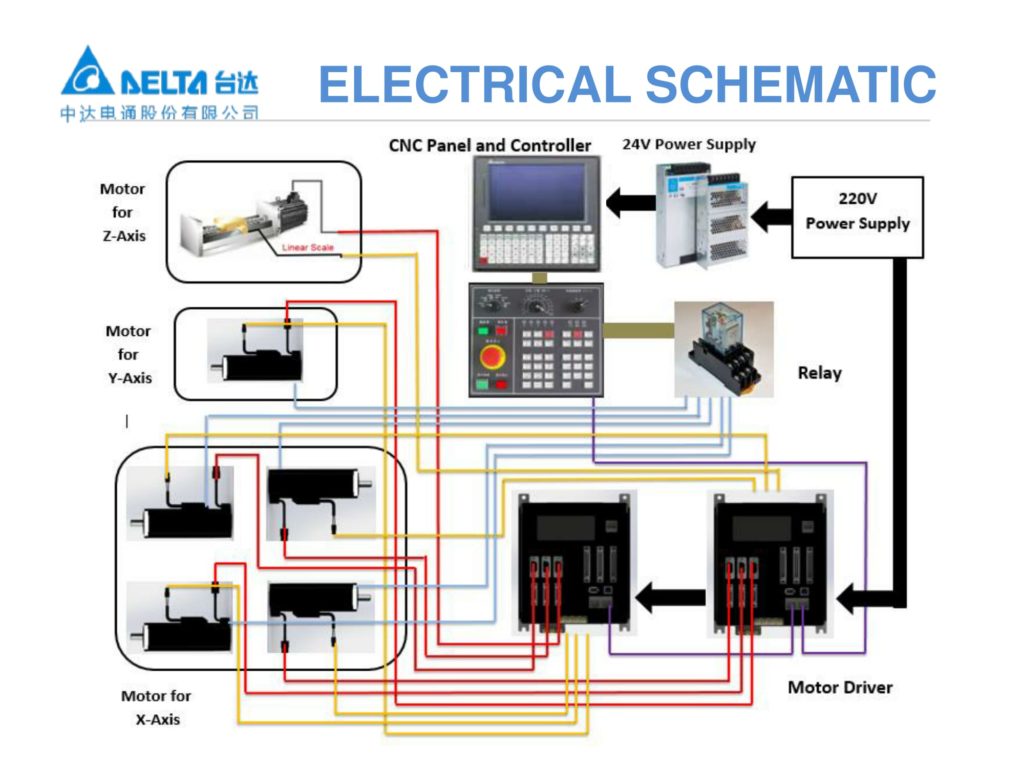

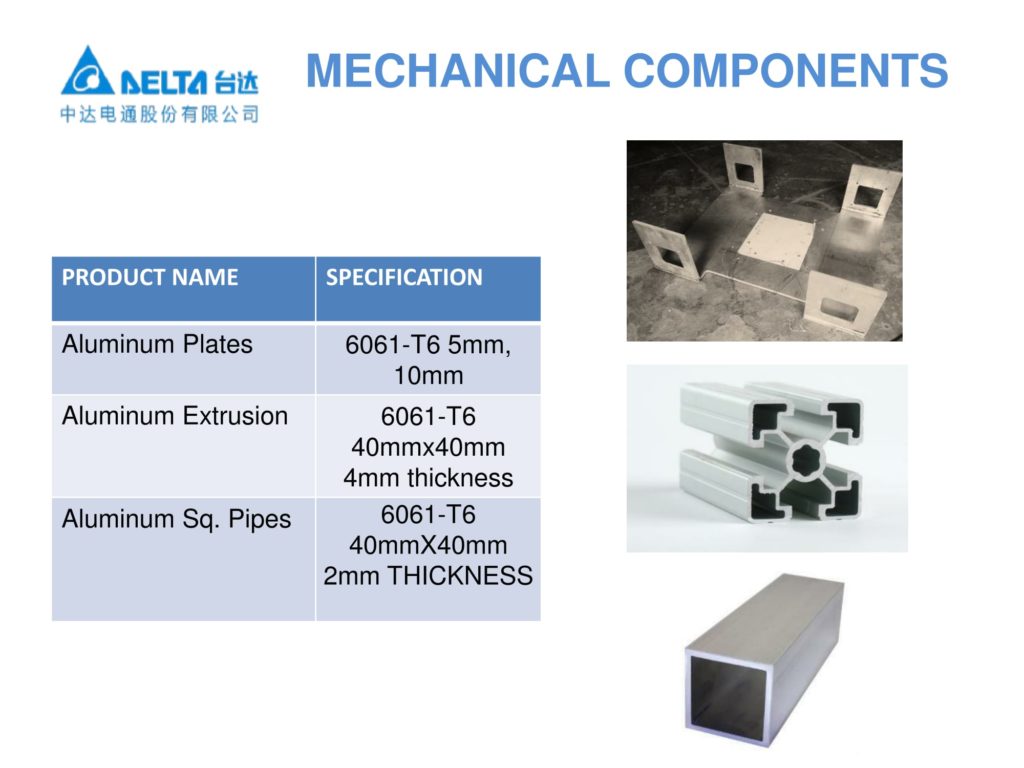

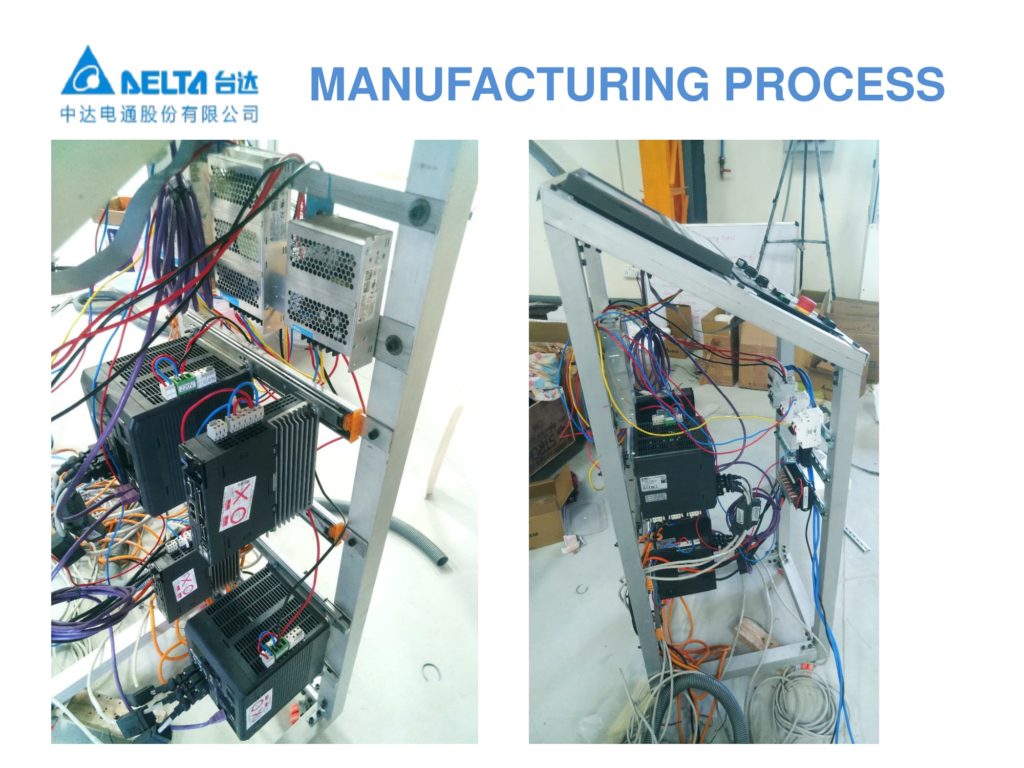

[SEE PICS BELOW] Our system is divided into three axes (X, Y, Z). The design consists of a base chassis on which the whole system stands. The base chassis houses all the servo drives, power supply, wiring, servo motors, etc. The base chassis has four servo motors that are attached to the gearbox, which are further attached with wheels. The chassis along with the wheels and servo forms the X axis. The X-axis moves horizontally parallel to the wall or work surface. Above the chassis runs vertically four aluminium extrusion which supports the Y axis for the system. The Y axis moves vertically up or down using one lead screw with split nuts attached to the base of a sliding rack. The lead screws are rotated by servo motors coupled to it and are placed inside the chassis. The Z axis is above the rack of the Y axis and moves two tools toward or away from the wall. An HMI/CNC panel is made separately to the side of the Machine for real-time monitoring, start, stop, emergency stop, etc.

Motion Control

In this project, we are using multiple servo motors for controlling X, Y, and Z axis motion.

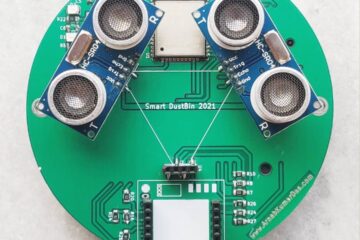

- In the X-Axis we will use four servo motors that gearbox coupled with four wheels in the base of the Machine that will work in coordination to move the whole Machine parallel to the wall. Feedback from ultrasonic sensors placed on the ends of Y axis rack, facing the wall, continuously measures the distance to maintain Y-axis parallels to the wall.

- In the Y-Axis we will use one servo motor directly coupled to one lead screw.

- In the Z-Axis, we will use one servo motor to move the printing head/laser head near and away from the wall.

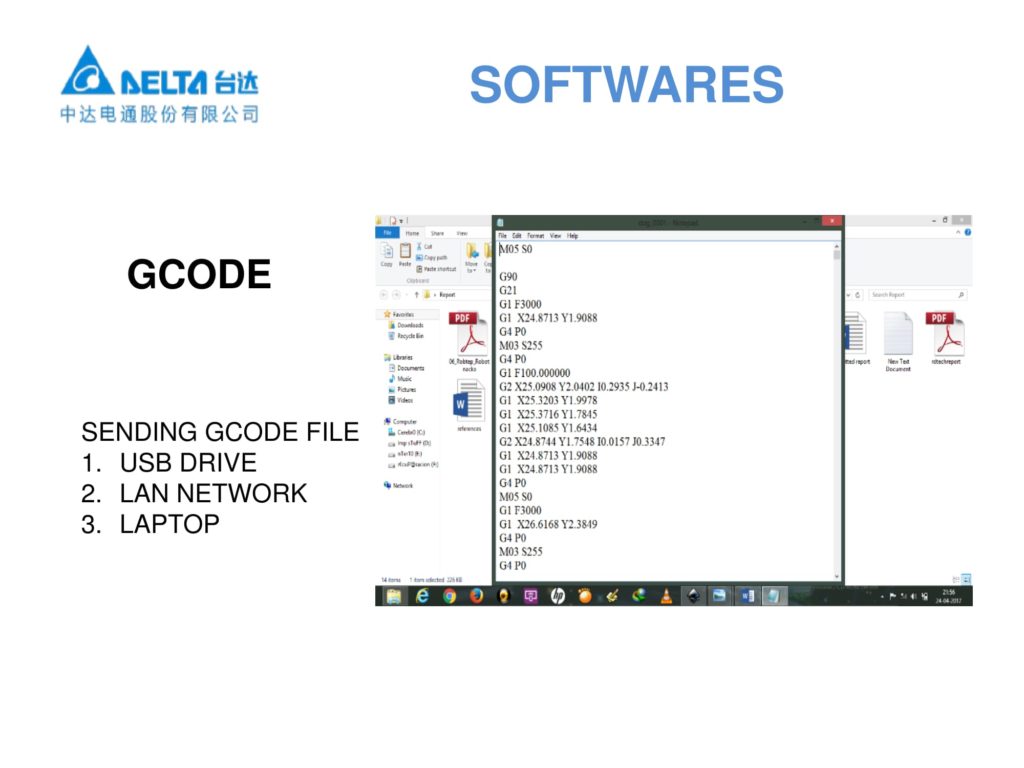

G-Codes are used for motion control with both linear interpolation and circular interpolation.

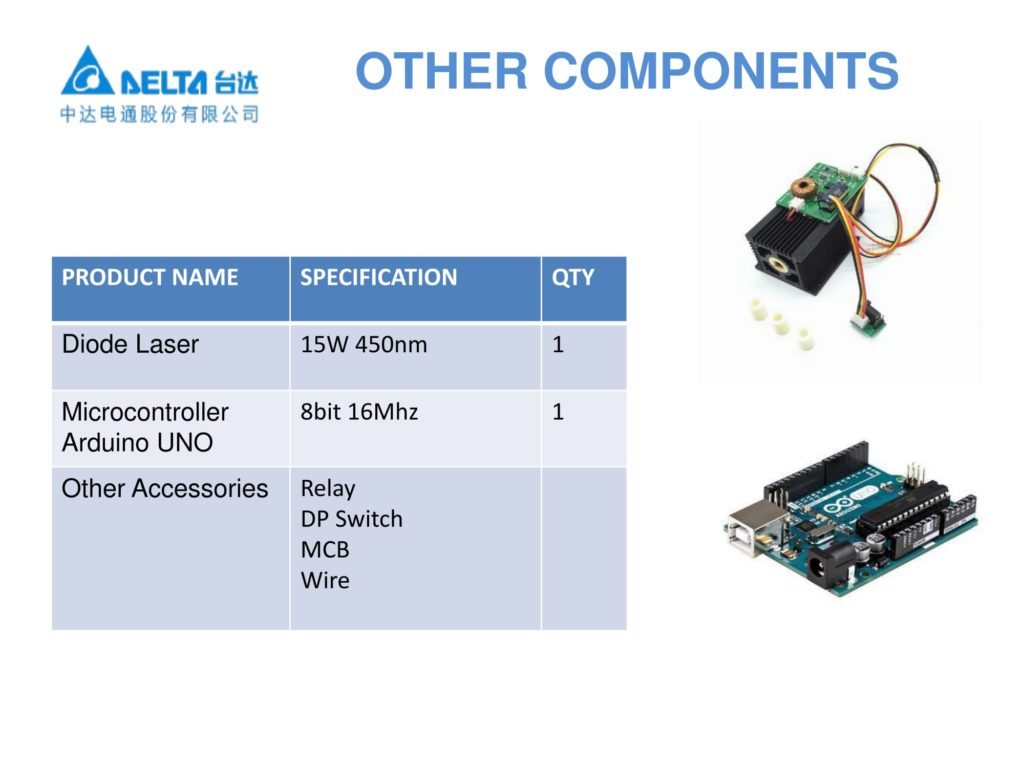

Tool Control

In this machine, we will be controlling tools that are mounted on the Z axis. M-Codes are used to control the tool. We control the laser intensity from the Z axis using M codes.

Workspace

- Cartesian Coordinate machine

- The machine can work only on flat-floor and flat-wall.

- Cannot move on a slanted floor (15 Degree Safe Limit)

- Cannot move past a locked door or closed door.

- Need clearance in his path for proper movement and operation.

KEEP SCROLLING DOWN FOR MANUFACTURING VIDEOS AND A GALLERY

NEWS ARTICLES ABOUT THE COMPETITION AND OUR WINNING

http://brandnews.deltaww.com/EN/34/BrandCommunityView.aspx?id=283

http://www.deltaww.com/news/pressDetail.aspx?secID=3&pID=1&typeID=6&itemID=7511&tid=0&hl=en-US

http://mkt.deltagreentech.com.cn/2017/jingsai/winnerslist.asp

0 Comments